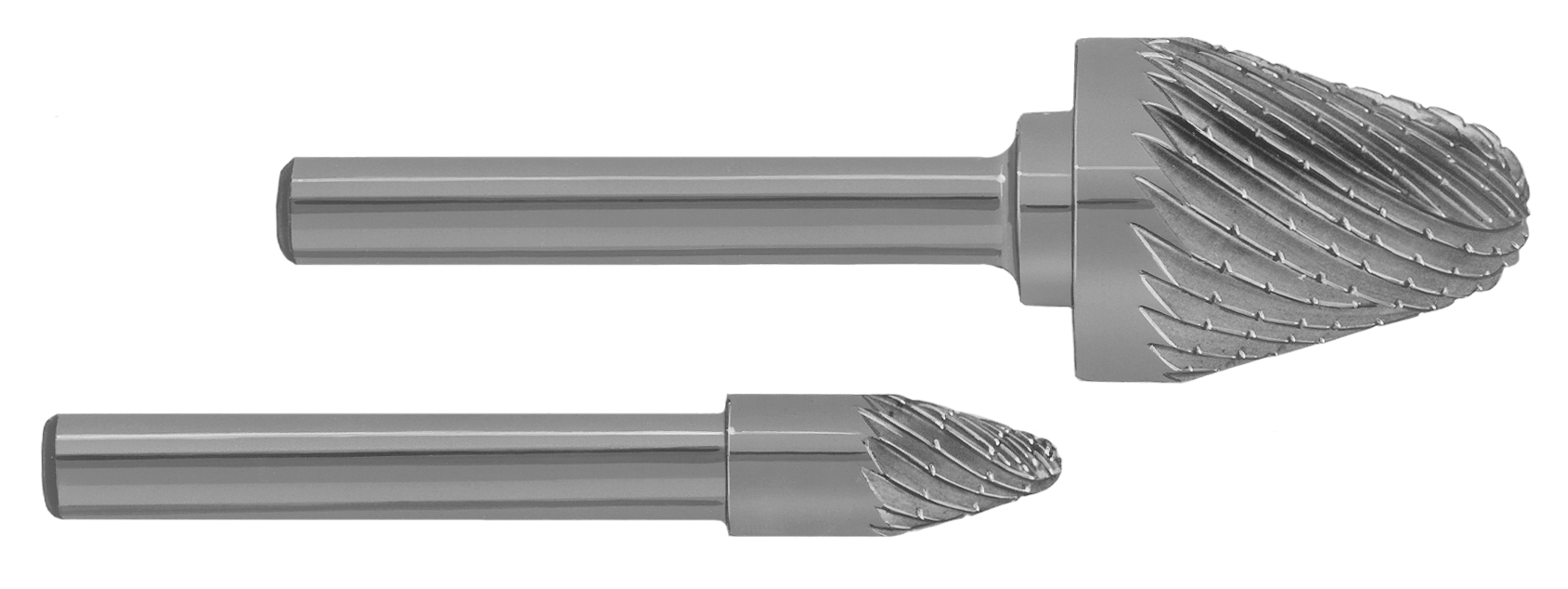

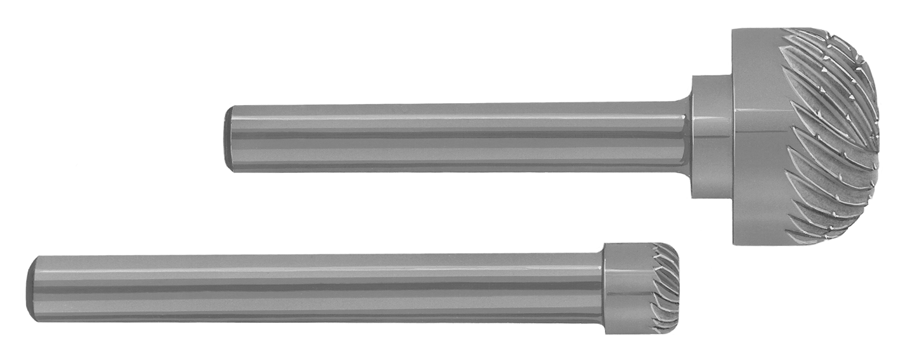

The Original Ground Rotary File

Invented by Rollin M. Severance in 1931, Midget Mills revolutionized precision deburring and finishing operations.

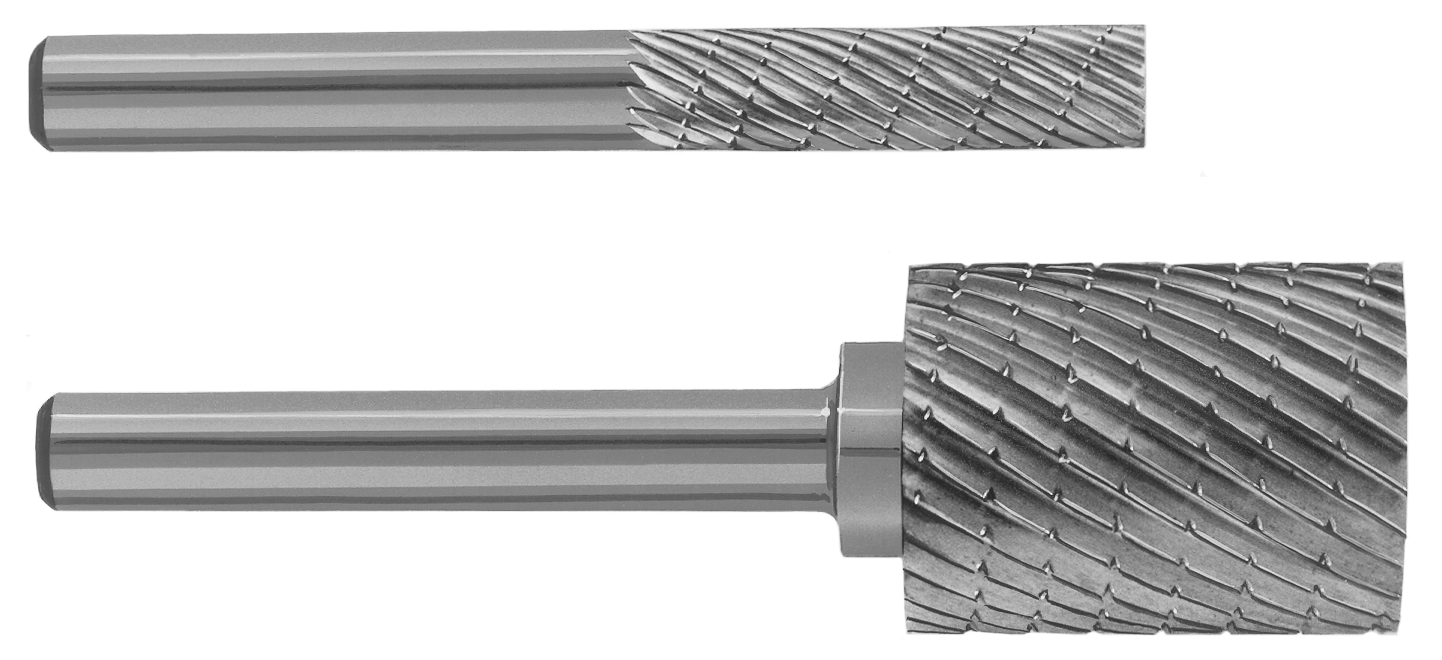

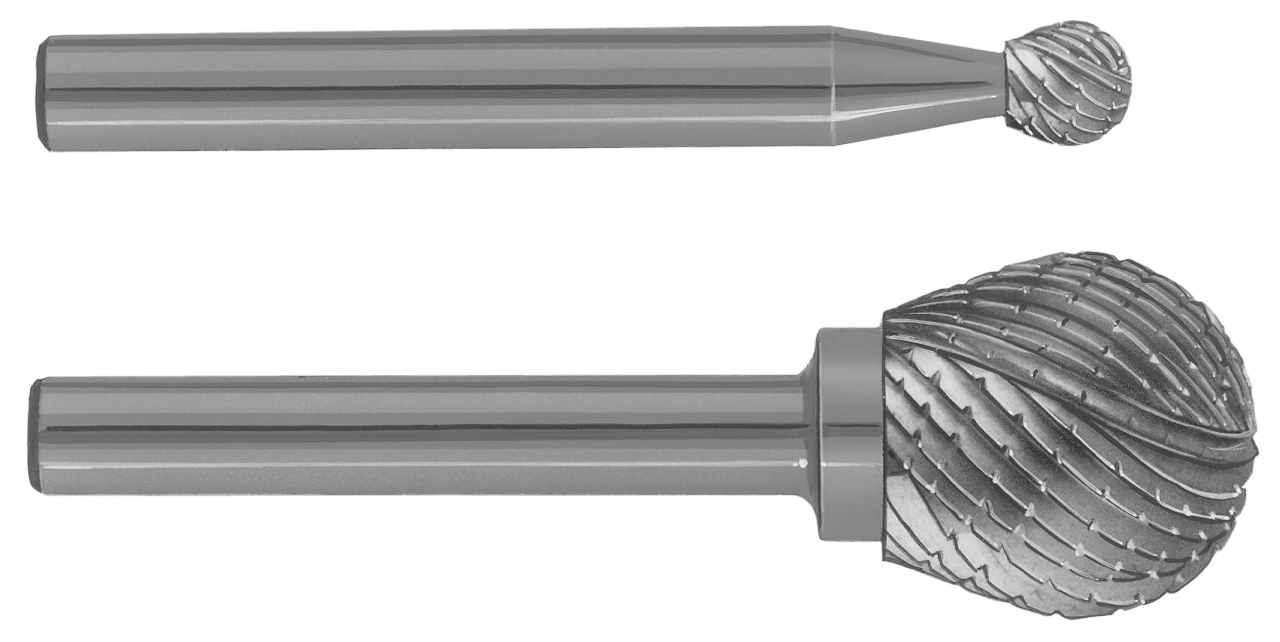

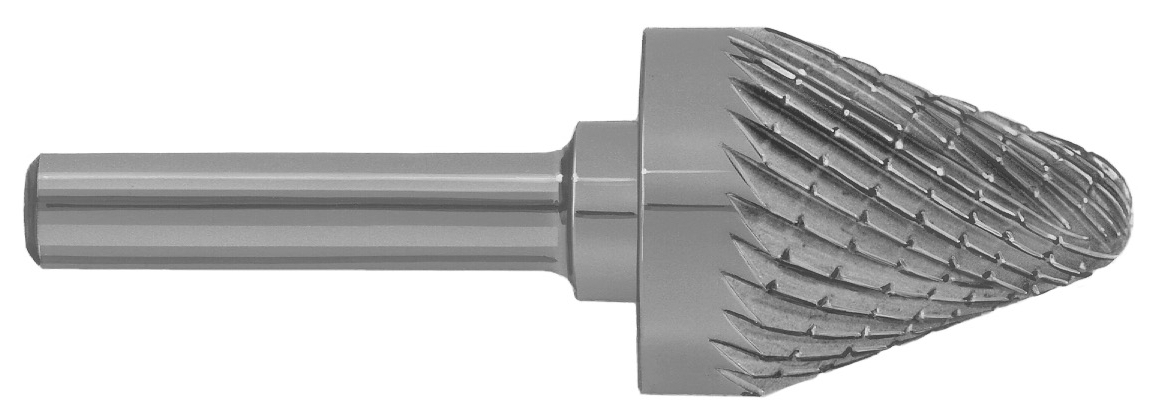

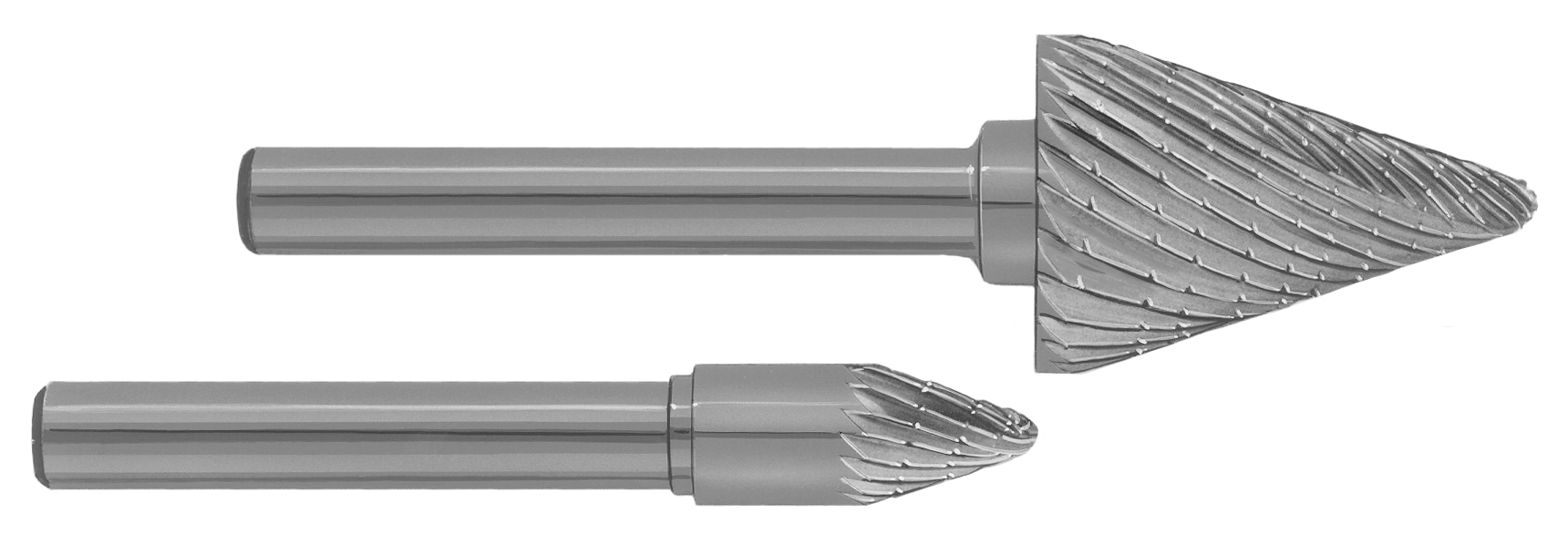

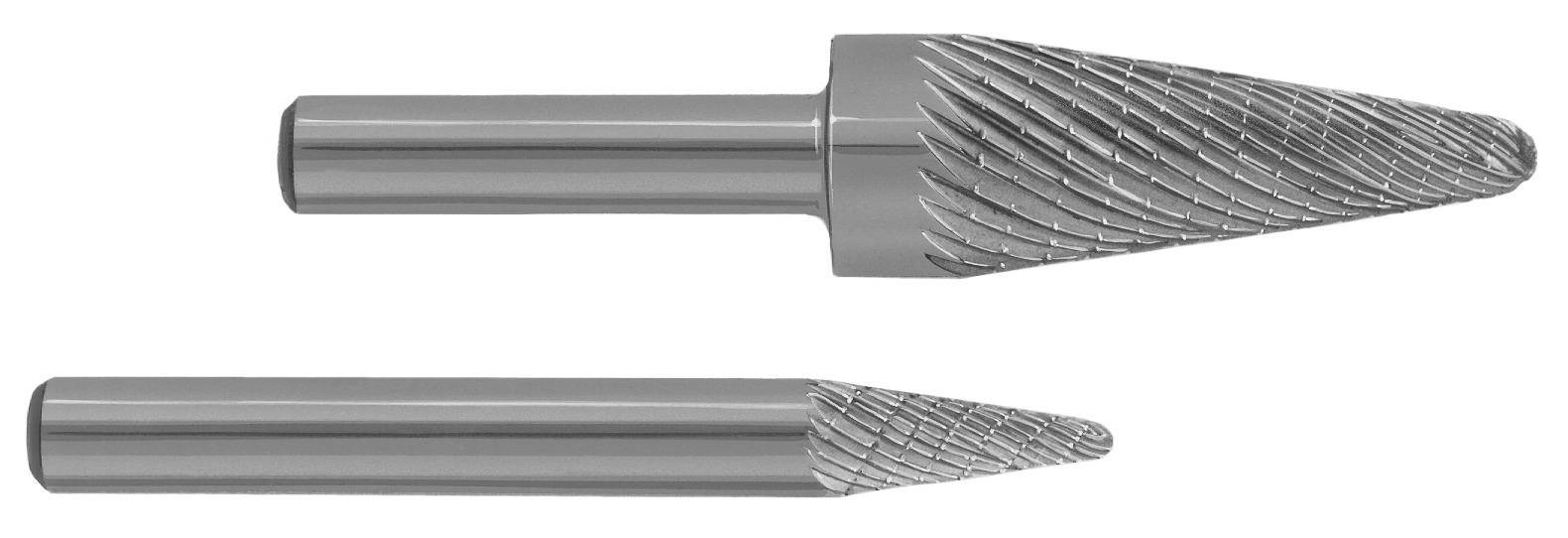

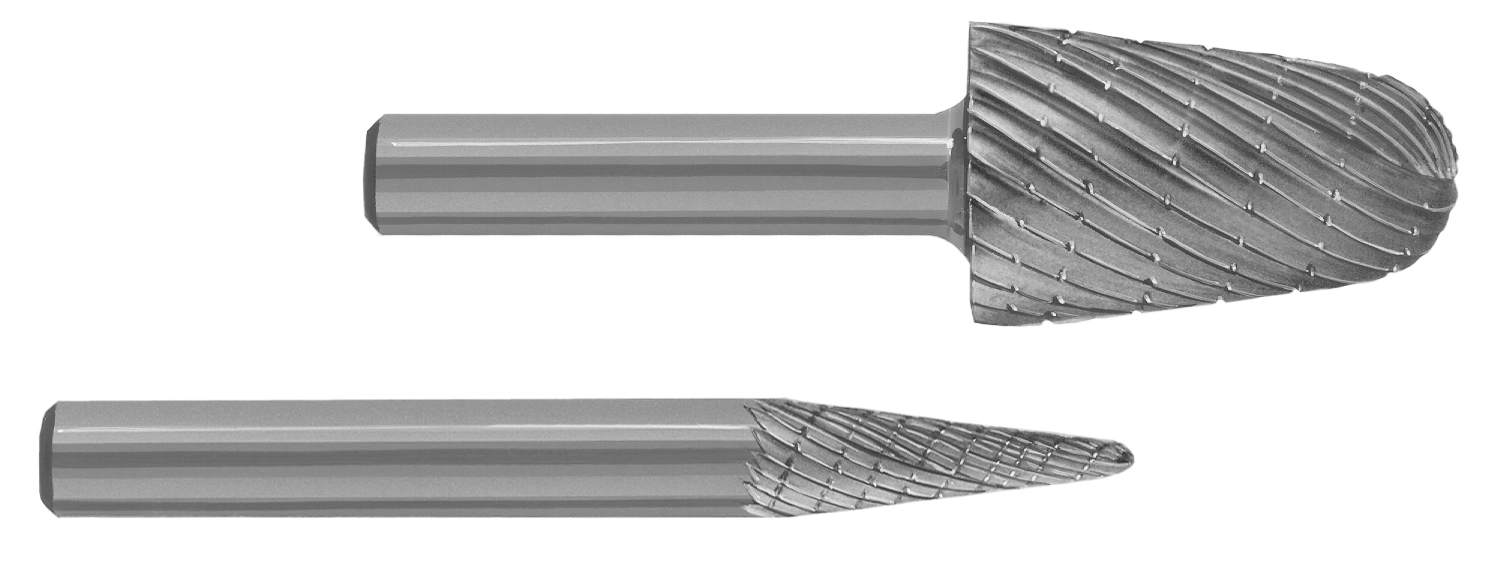

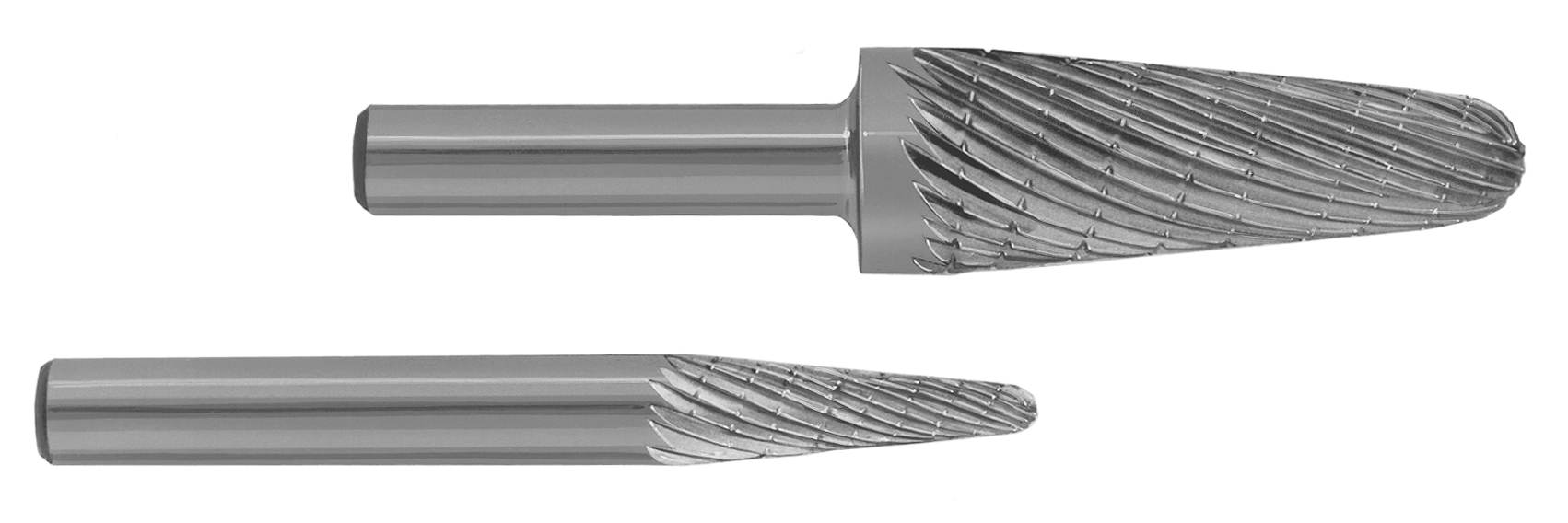

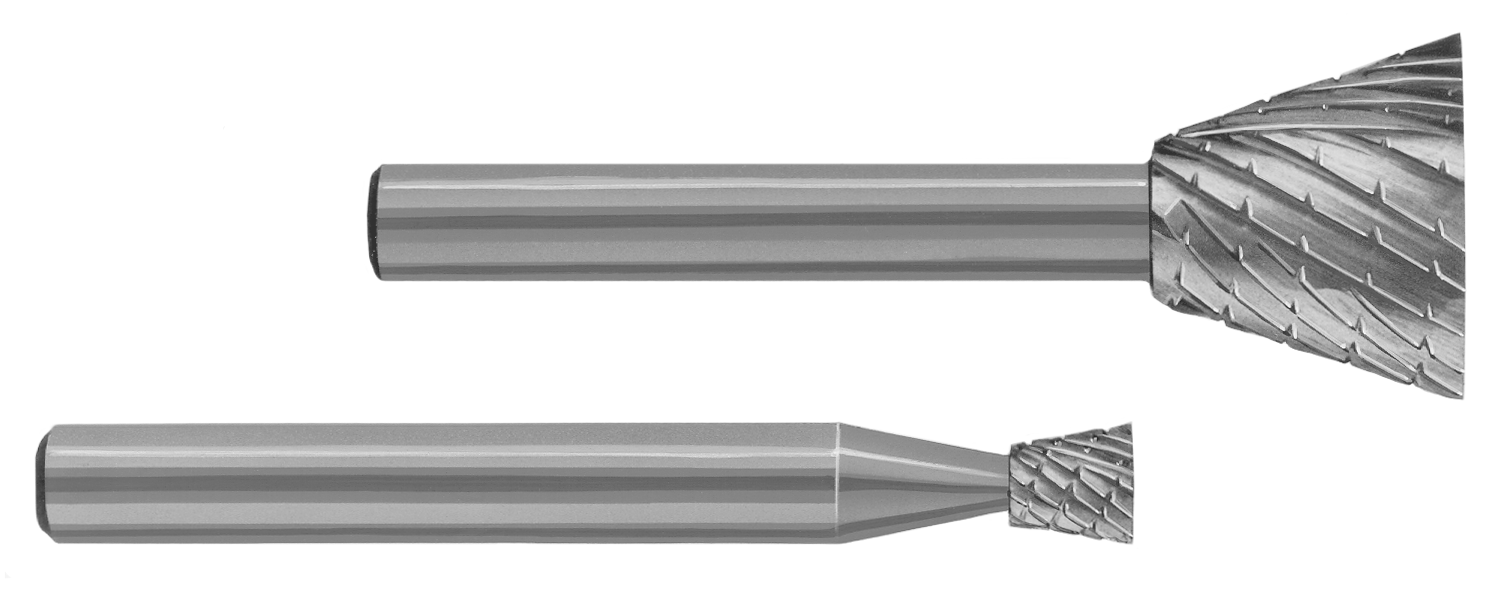

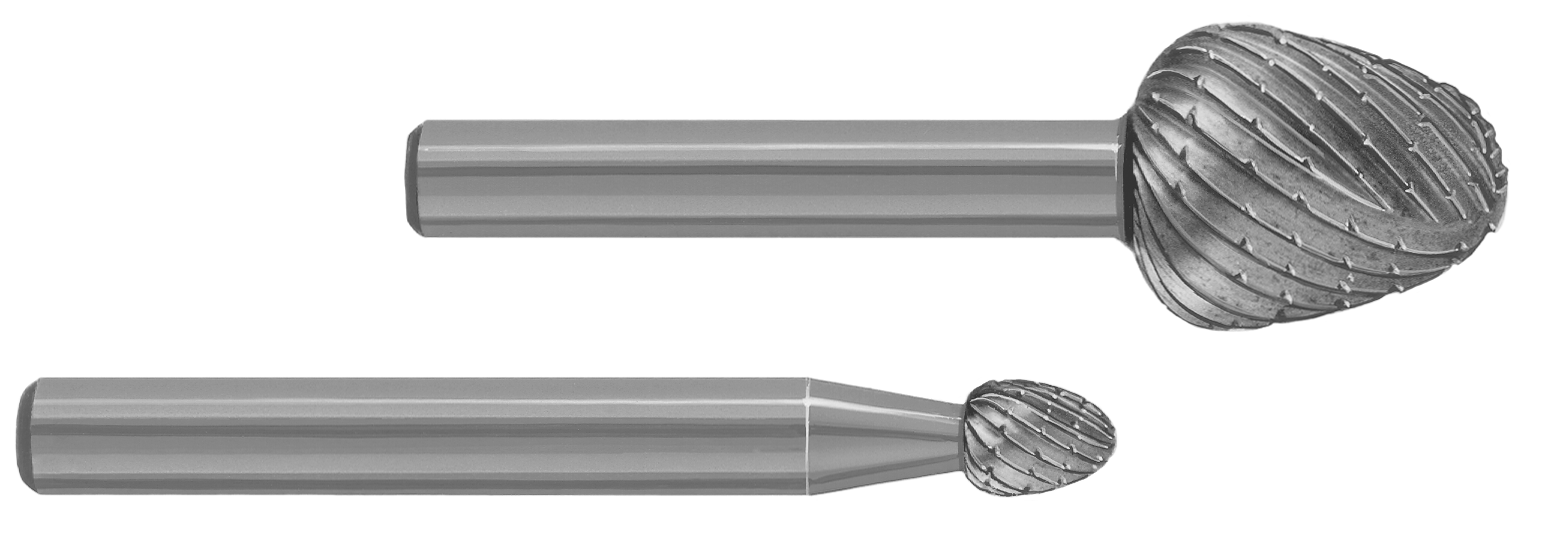

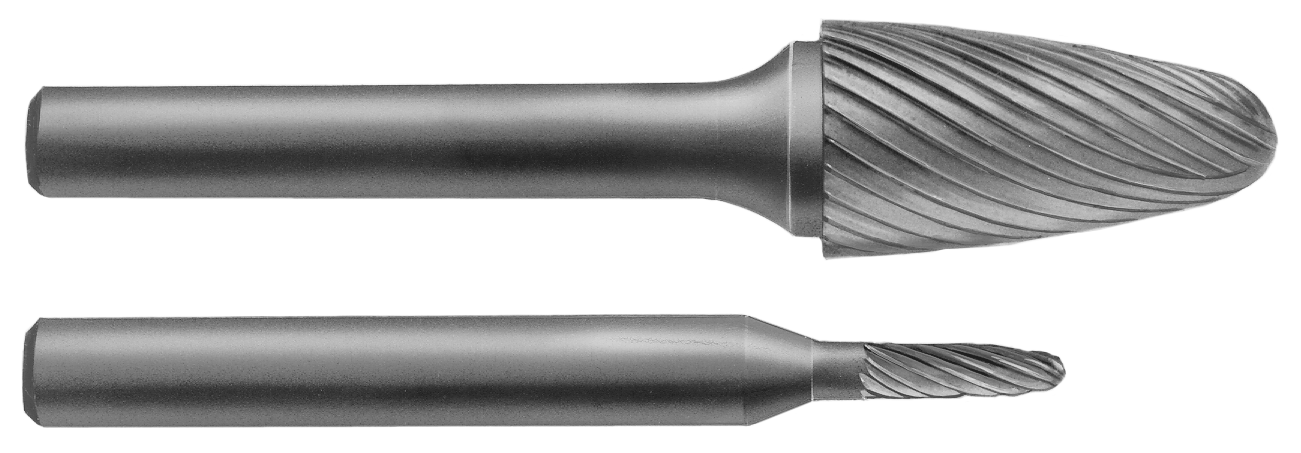

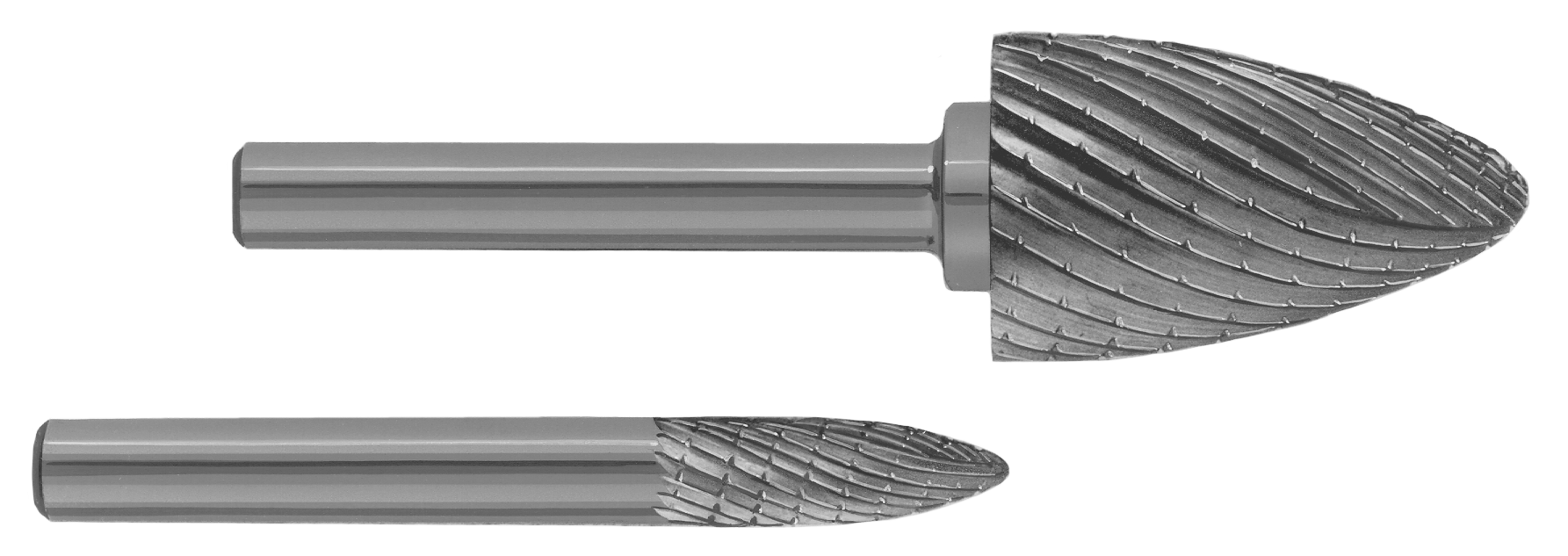

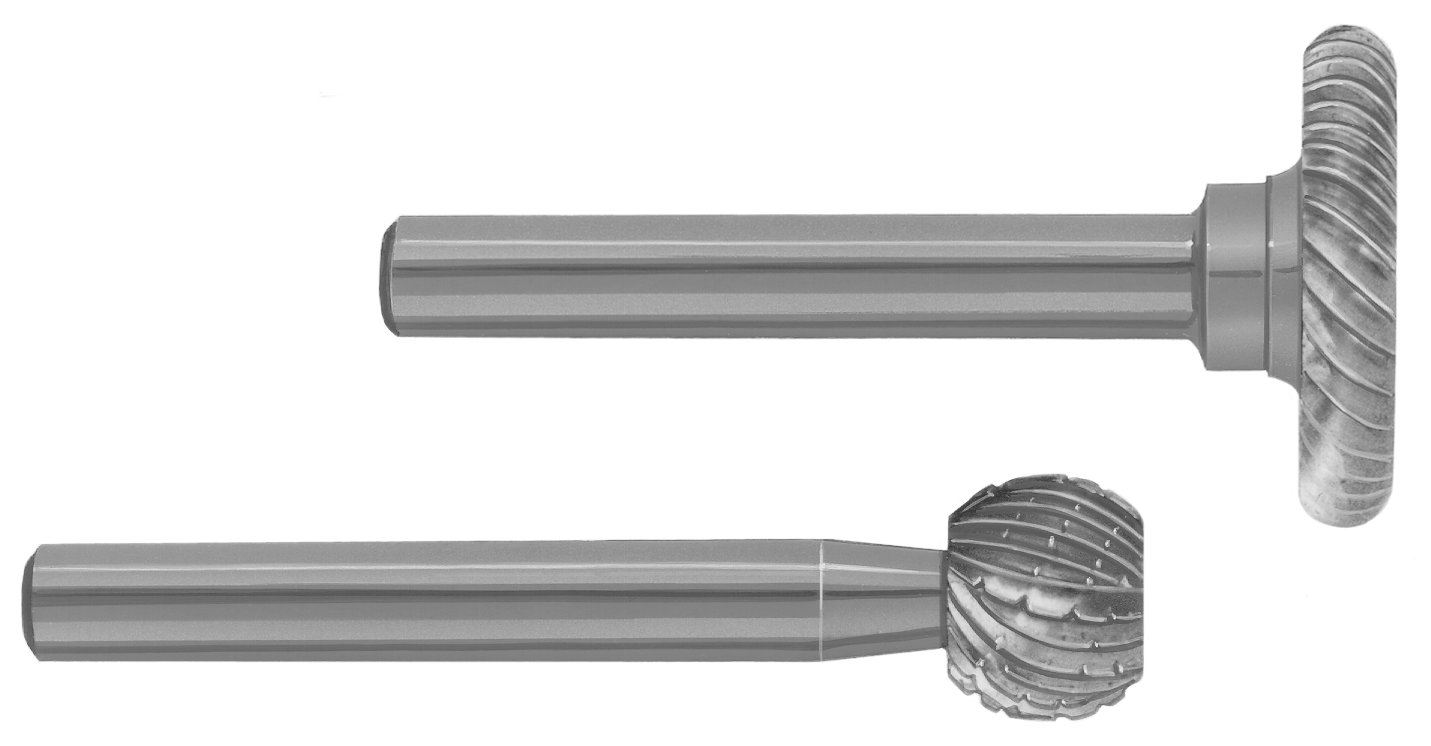

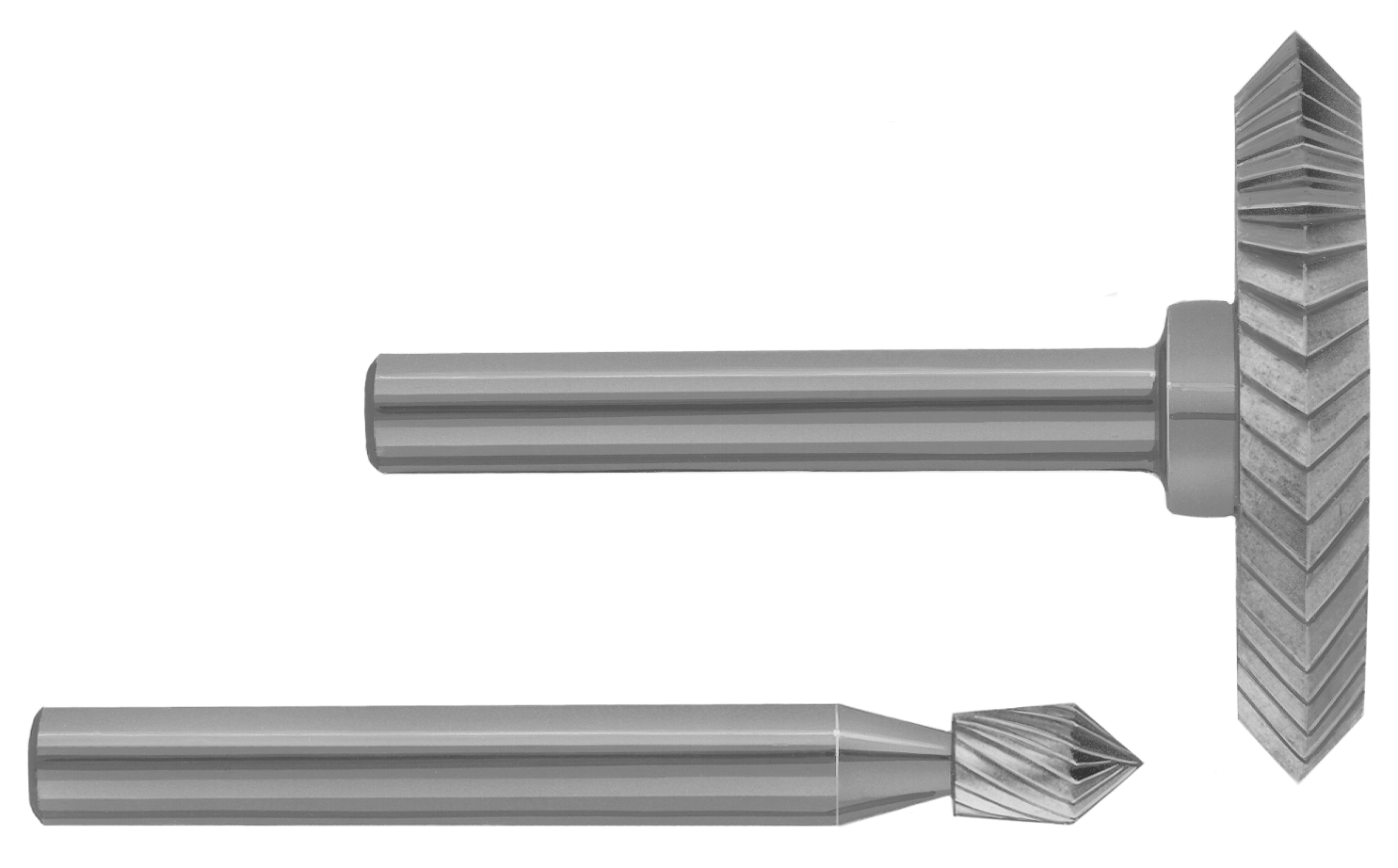

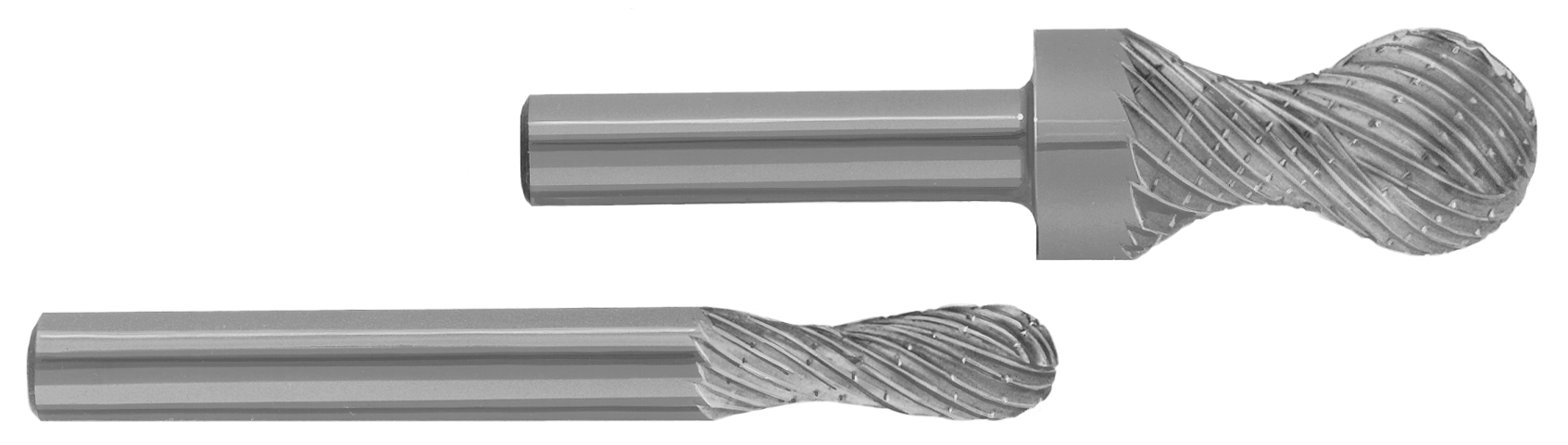

Severance Midget Mills are precision ground rotary files designed for deburring, finishing, and shaping operations. Unlike stamped or milled burs, each Midget Mill is individually ground to exacting tolerances, ensuring consistent performance and extended tool life.

"We are the originators; we have been copied but not surpassed."

Ordering Tip

All tools are ordered by their EDP Number (Electronic Data Processing). Find your tool in the tables below and use the EDP number when placing orders.

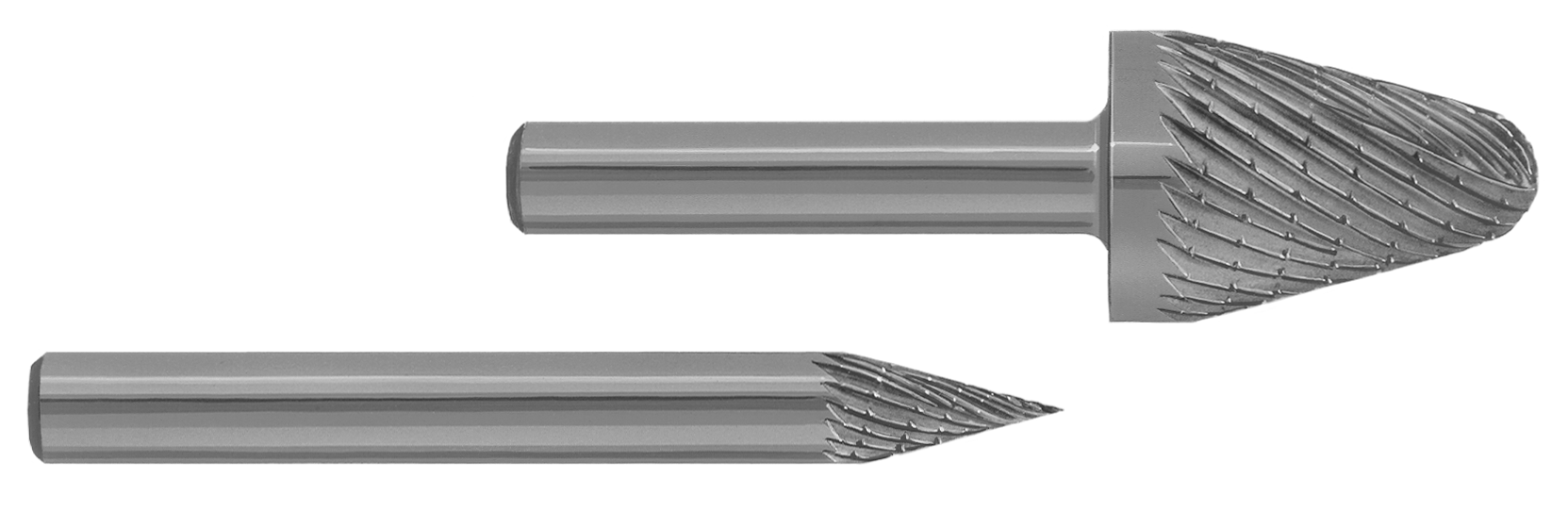

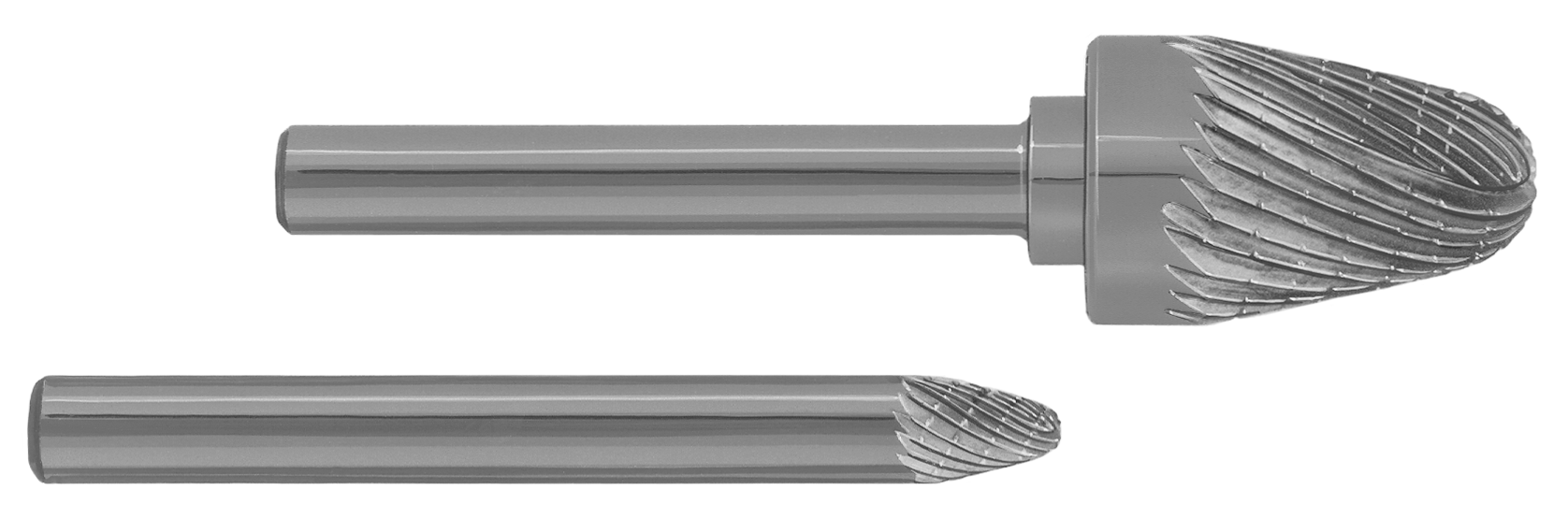

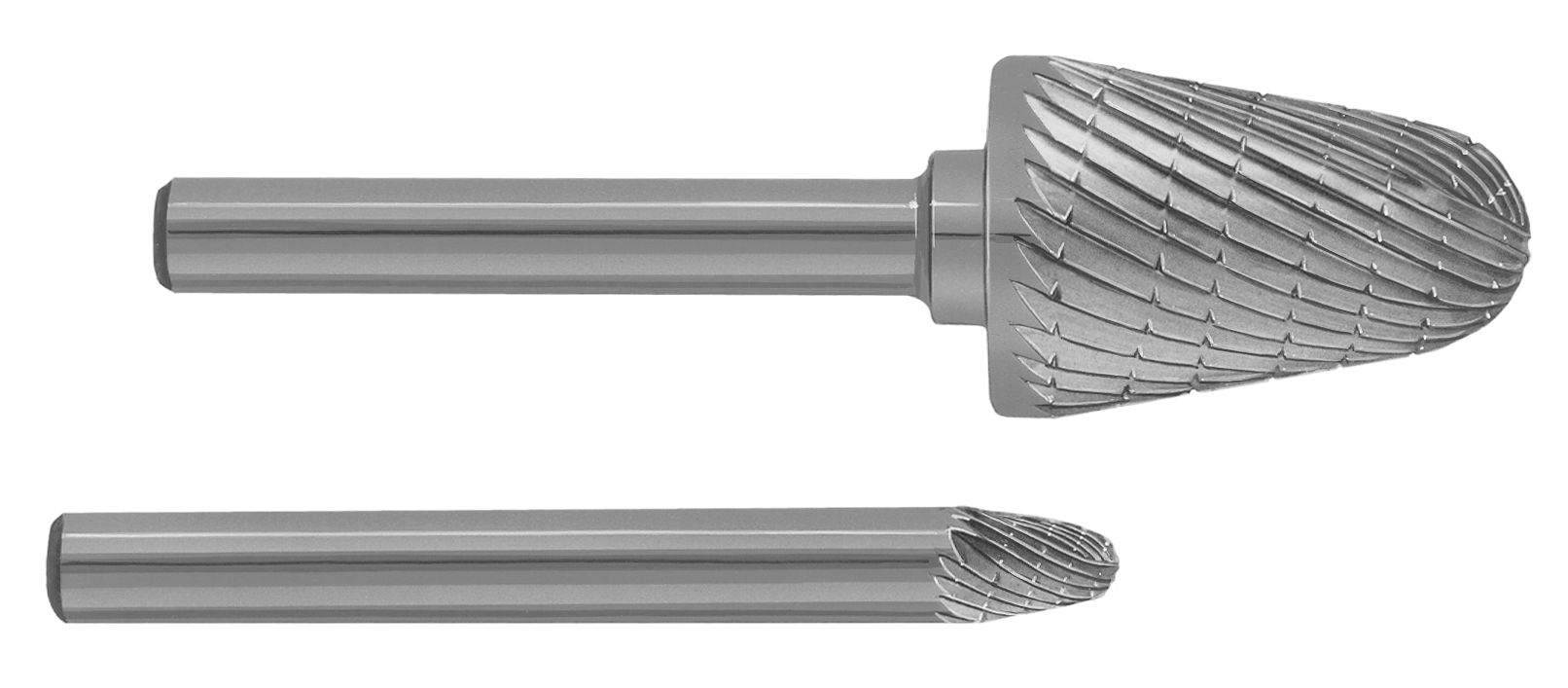

Key Features

- Precision ground flutes

- Available in 24 shapes (A-Z, FL)

- HSS and Carbide options

- 1/4" standard shank

- Resharpenable

- Made in USA